Functional Substrate and Film

- Transparent Conductive Film

ITO-PET(Table can be dragged)Typical Values Total Thickness (micron) 100,125,175 PET Residual Shrinkage Value

(%TD and % MD)1.0%TD

1.5%MDHeat Stabilized PET Residual Shrinkage Value

(%TD and % MD)≤ 0.2 Electrical Resistance(ohms/sq.) 50 Visible Light Transmission(%Tvis) 87 Haze(%) 1.0 Color b*(CIELAB D65/10) 2.5 ITO Coating Adhesion (R/Ro) 1.0

Non-ITO-PET(Table can be dragged)Typical Values Total Thickness(micron) 125,175 Heat Stabilized PET Residual Shrinkage Value

(% TD and % MD)≤ 0.2 Electrical Resistance (ohms/sq.) 15 Visible Light Transmission (%Tvis) 82 Haze(%) 1.0 Color b*(CIELAB D65/10) 8.5 ITO Coating Adhesion (R/Ro) 1.0

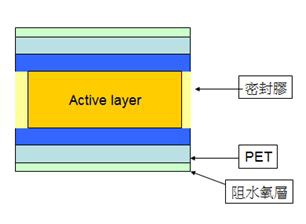

- Barrier Film

Total Thickness(micron):50-300um

Barrier PET

WVTR(g/m^2/day):E-1 to E-4

Visible Light Transmission(%Tvis):>85%

Coating Ink

- Conductive Ink

Ex1. CNT ink(Table can be dragged)典型值 Electrical Resistance

(ohms/sq.)15-70 70 Ω/□ @200 nm Visible Light Transmission (%Tvis) 74-91 91%@200nm Drying Condition 110°;C/4minsViscosity(mPas) 3-8 Surface Tension/Dyne Level

(mN/m or dyn/cm)38-42 *Printing and Coating Process: Slot Die, Spin, Inkjet and Spray

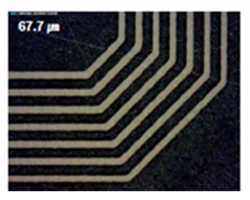

Ex2. Ag Ink and Paste

Viscosity:Min<10,Max 300.000cps

Sheet Resistance:<300 mΩ/□(Non-transparent Circuit)、≦15Ω/□(Transparent Circuit)

Curing/Drying Temperature:Min≦120℃ (Non-transparent Circuit)、Min≦110℃(Transparent Circuit)

- Sealant

Viscosity:Min<600,Max≧112,000 cps (be able to customize)

WVTR:about 1 g/m2/day